How To Remove Spring Hinges

Hinges

Introduction

This commodity gives y'all a comprehensive guide to hinges.

- What is a Swivel?

- Types of Hinges

- Hinge Components and Characteristics

- Design Considerations

- Common Manufacturing Processes

Affiliate i: The Definition of a Swivel:

A hinge is a auto element that connects two bodies allowing angular movement nigh a stock-still axis of rotation, all the while preventing translations and rotations on the remaining 2 axes. A hinge tin can be considered as a journal begetting with just one degree of freedom where a shaft is rotating in a hole. Hinges only permit ane rotation, either yawing (the most common), pitching, or rolling.

Hinges are a jointed and flexible device that is attached to any swinging role. Hinges are mechanical bearings that are used to connect two swinging objects or points to one another and give them the liberty to movement relative to each other. Hinges have limited movement, assuasive the joint to move only at one angle and restrict the other movements of swinging parts.

Hinges are commonly used in doors, enclosures, containers, article of furniture, jewelry, construction, and electronics. For every application, there is a suitable design of hinge available. For a unique awarding, it is besides possible to pattern and industry a custom hinge at a low cost.

Affiliate 2: Types of Hinges

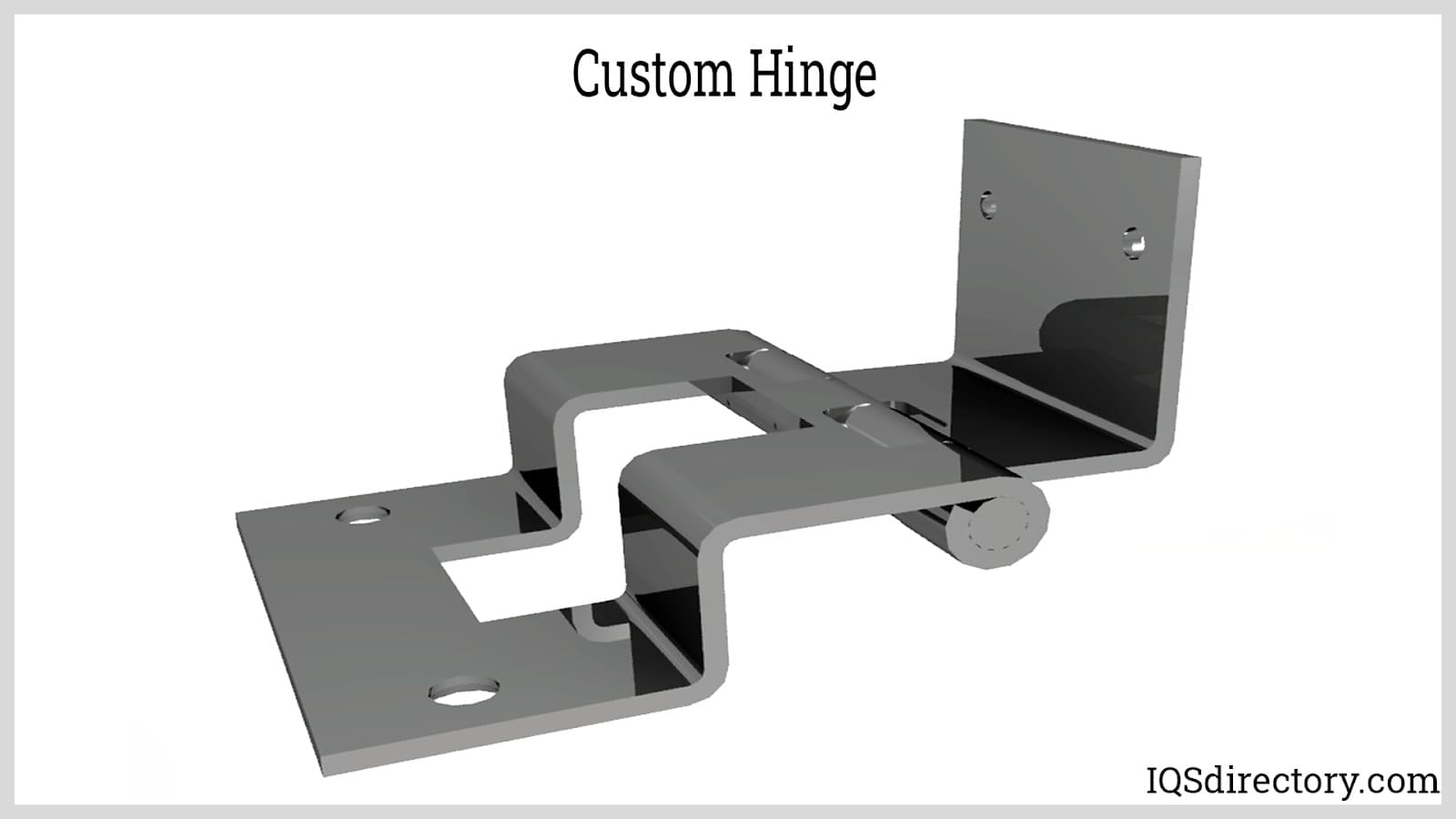

In that location are a multifariousness of types of hinges to cull from for every awarding. For indoor furniture, either barrel or curtained hinges are used. For chief entrance doors, sheds or wooden gates, butterfly and strap hinges provide decorative styles. For industrial electric enclosures, friction and geared continuous hinges are used. If none of the hinge types fit your requirement, it is e'er possible to design a custom hinge. Below are the hinge types available in the market.

-

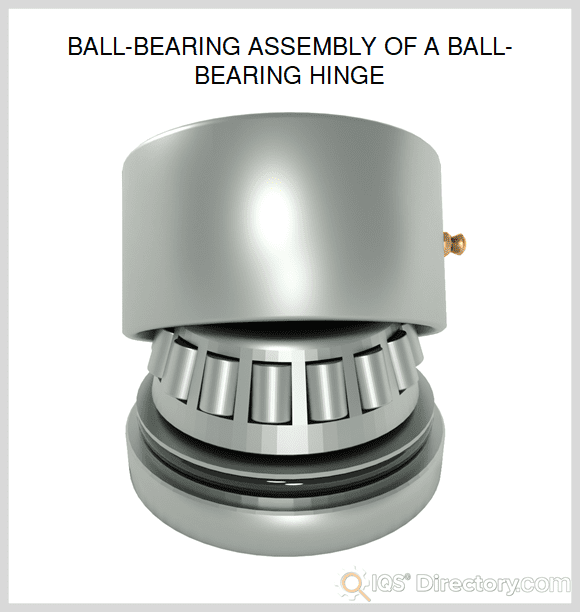

Ball-bearing Hinges:

Instead of the usual journal-begetting type, knuckle-and-pivot assembly, brawl bearings are used primarily to reduce friction. Ball bearings minimizes friction past decreasing the signal of contact betwixt rubbing surfaces while providing back up for radial and axial loads.

-

Block Hinges:

These are mostly heavy-duty hinges attached to the parts either through welding or bolting. A block hinge has a barrel fabricated of galvanized steel with a thick, square profile held together by a pin made from stainless steel for additional corrosion resistance.

-

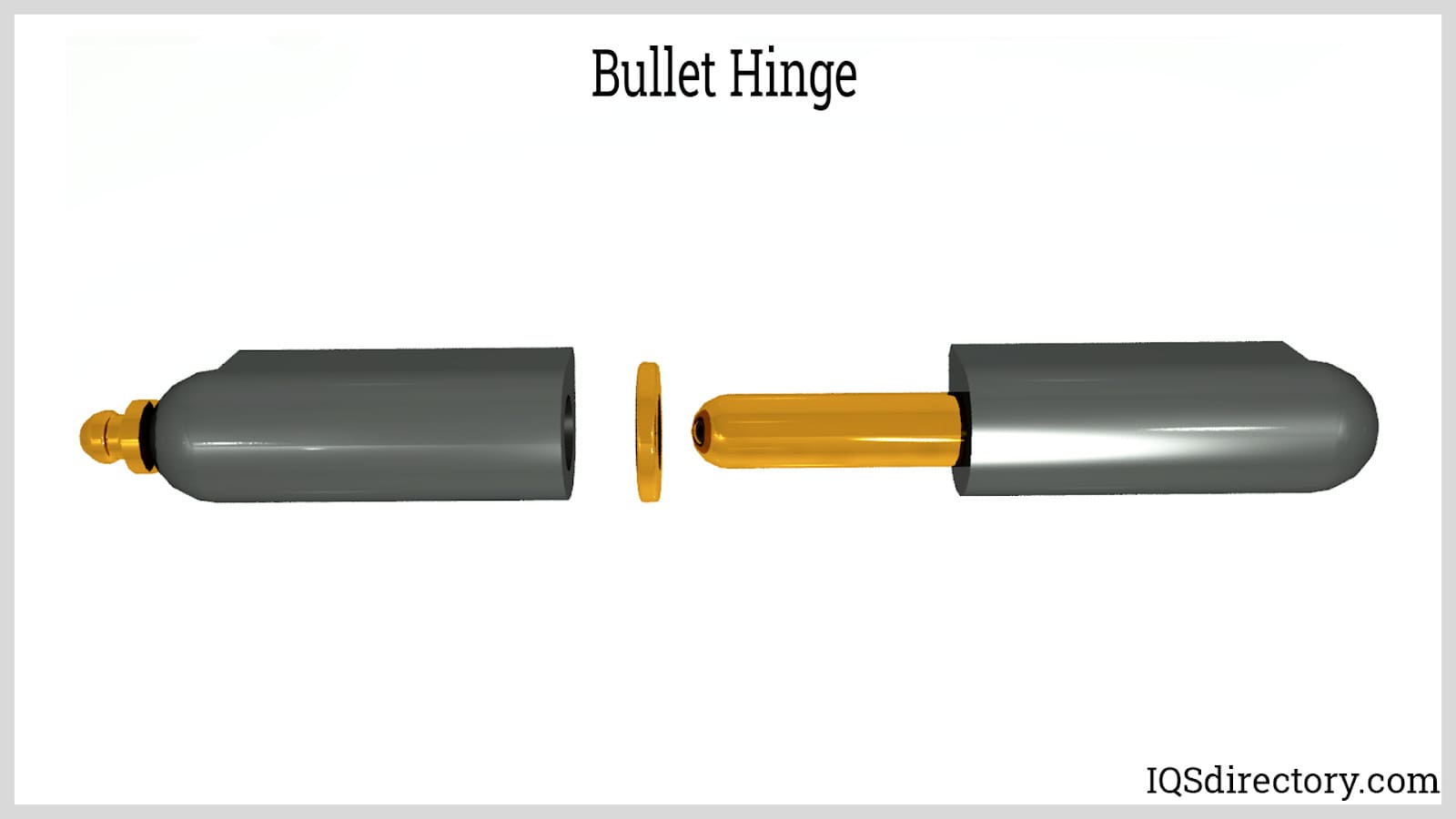

Bullet or Barrel Hinges:

This type of swivel is composed of two barrels with 1 attached to each of the parts. Separating the barrels is a low friction bushing or some other barrel. Bullet hinges exercise not take a foliage for zipper; rather, it uses welded joints. Bullet hinges take the advantage of being installed at narrow frames while providing strong back up.

-

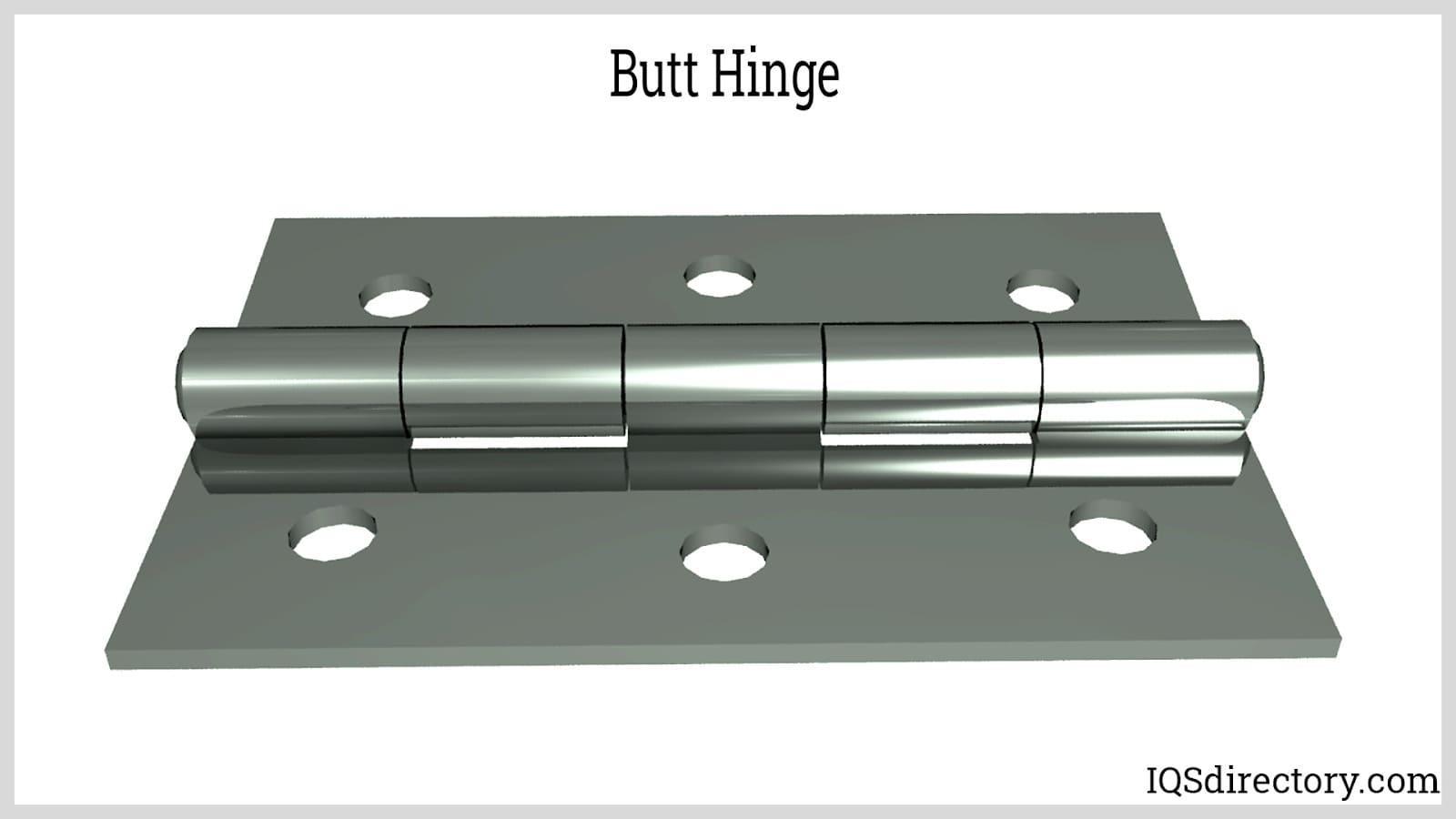

Butt Hinges:

A butt hinge, besides known as a mortise hinge, is the most common type of hinge used on doors and windows. It is composed by a pair of leaves with several knuckles attached by a shaft or pivot. Ane leaf is attached to a moving component (the door) while the other is fastened to a fixed trunk (the door jamb). The only thing that is visible when the door or window is closed is the shaft that has a pin placed in it. Barrel hinges are used for indoor and outdoor utilise. For indoor use they are made of steel for use in cabinets, though for outdoor employ these are fabricated of anti corrosion stainless steel. Butt hinges are about six inches in length or shorter. Ordinarily, the hinge is flushed to the wood surface through a mortise, hence the name. This hinge can be total or half mortise. Full mortise means both leaves are flushed to the surfaces of the door and door jamb, while half mortise involves merely ane leaf is flushed (usually the moving component).

-

Butterfly Hinges:

Butterfly hinges are like barrel hinges but with added aesthetics to the design. They are usually used in furniture doors for adding decorative features where strength is not particularly important.

-

Example Hinges:

Case hinges are similar to butterfly hinges simply are commonly used in suitcases, briefcases and so along.

-

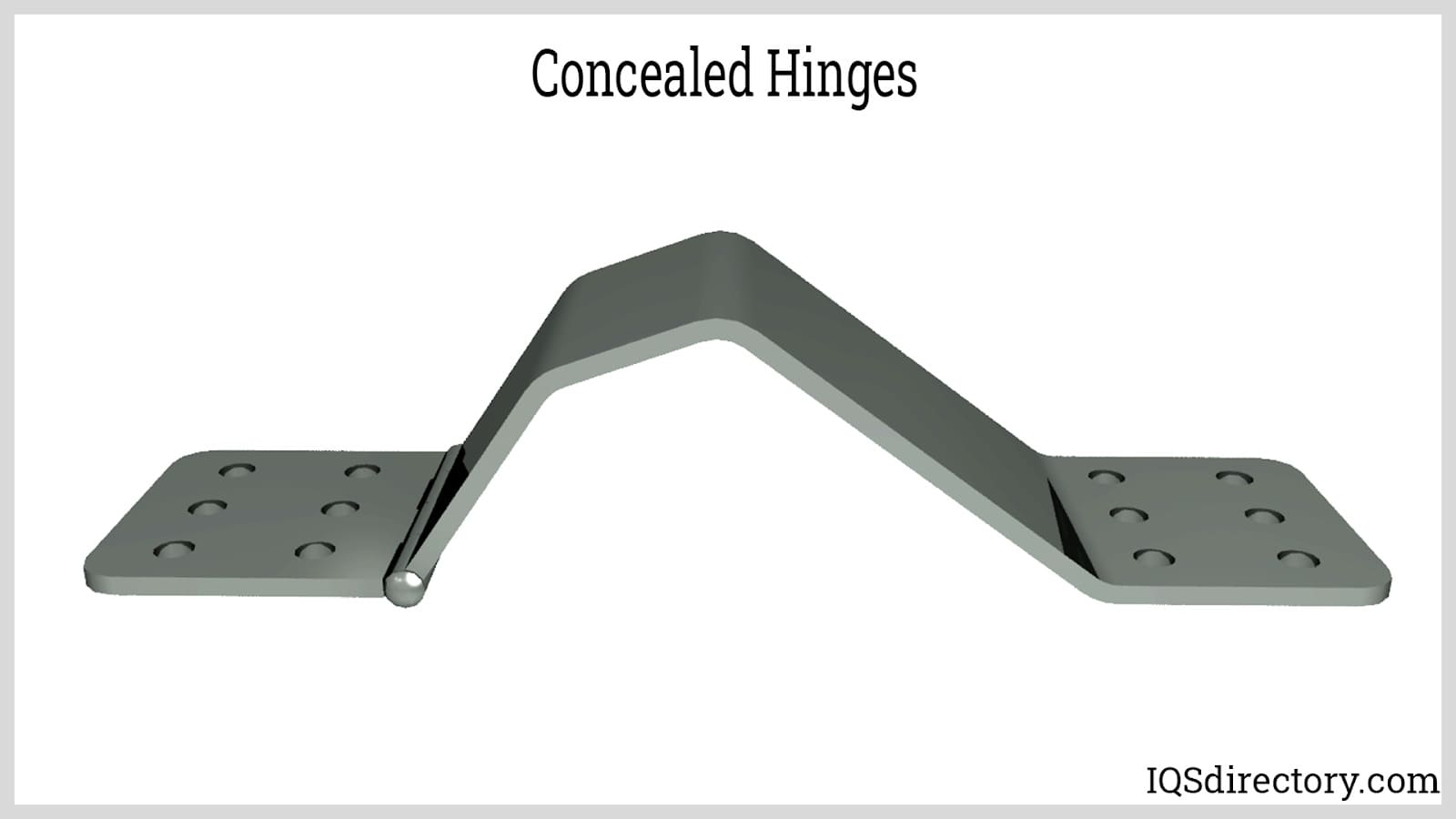

Concealed Hinges:

Like barrel-type hinges, this blazon of hinge is usually used in furniture doors. This hinge consists of two parts, the hinge cup, and the arm. Concealed hinges, besides chosen cup or Euro hinges, are complicated in construction and have several design features. They cannot be seen from the exterior making the piece of furniture accept a continuous appearance. These hinges help in freestyle rotation and tin open in a small radius. They are more often than not used in wooden cabinets. Its three movements in three unlike dimensions make information technology useful for many purposes. As well, this type tin can be adapted after installation making viable for constructions with slight imperfections. Aside from beingness adaptable, some designs besides take cocky-endmost features and damping systems.

-

Continuous Hinges or Piano Hinges:

Continuous hinges are a variation of the butt hinge simply are constructed longer and narrower. Piano hinges take long narrow leaves that come across the whole length of the door or the window to give actress strength and support to the object. This hinge spans the entire length of the door or lid providing strong support. Information technology is sometimes referred to as a piano hinge since this is commonly used to attach piano lids to its torso. Continuous hinges can also be mortised to the surface they are fastened to. These can be constitute in very specific places such as desk doors, tool boxes, cabinets or doors.

-

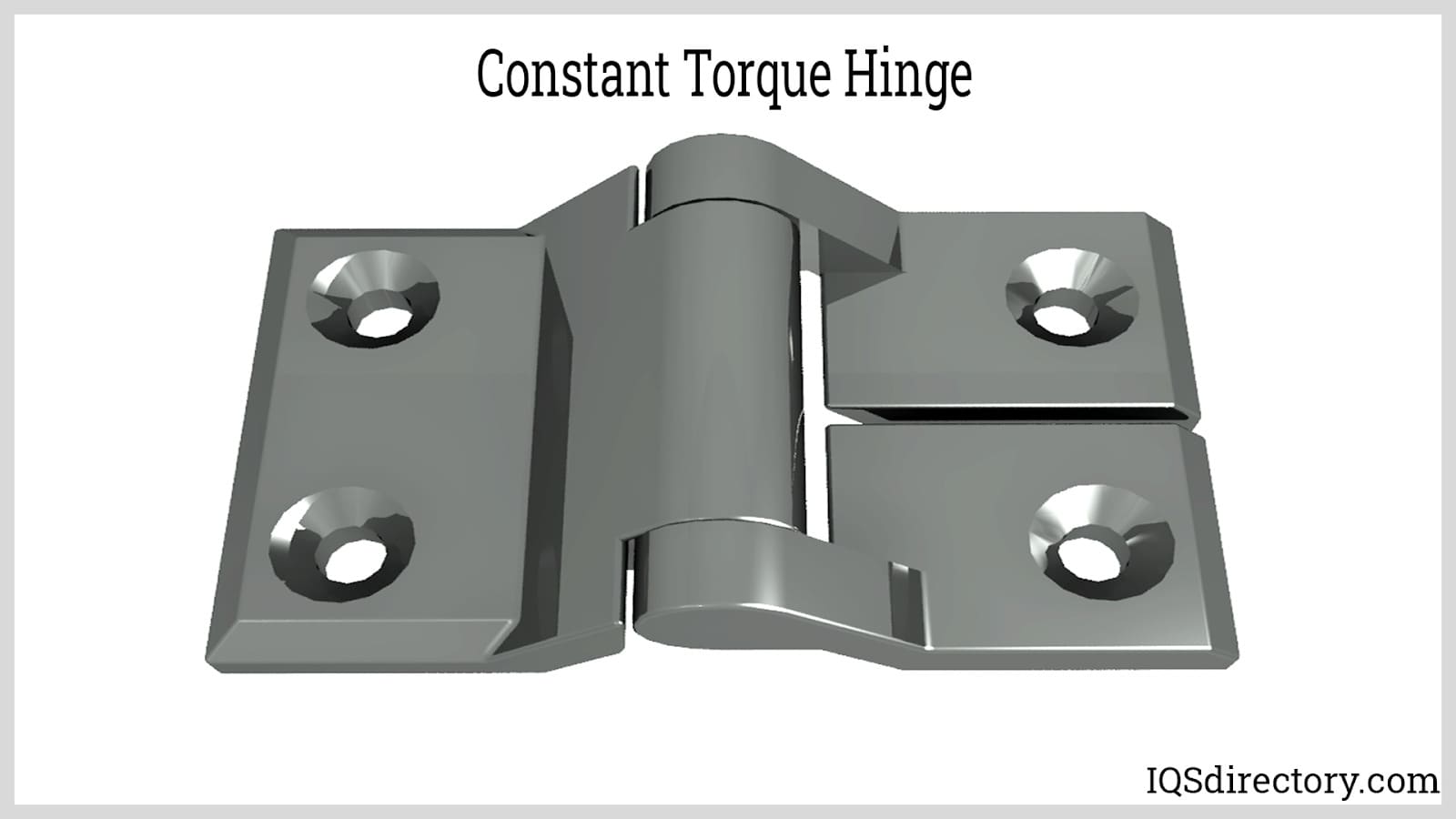

Constant Torque Hinges:

This type of swivel is designed to provide abiding resistance while being opened or closed. Constant torque hinges are characterized by their preset torque specifications and cycle lifetime. Torque hinges are used in holding doors and flaps in whatsoever desired position past its forcefulness of friction. These hinges are used in monitors to arrange the angles.

-

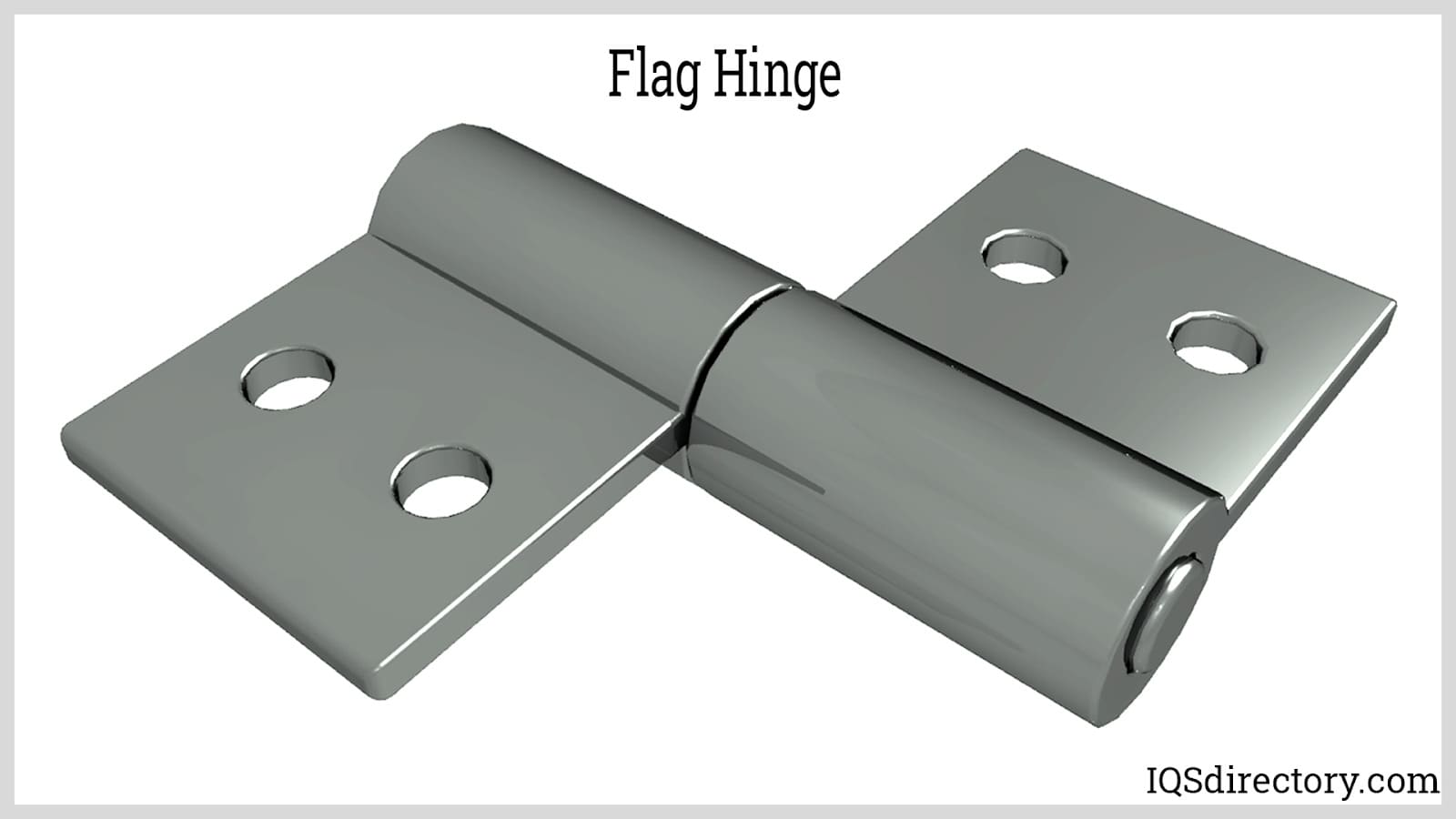

Flag Hinges:

The flag hinge consists of a pair of leaves (male and female) with the pin permanently fastened to one leafage. The male person leaf has the pin permanently attached to the plate which resembles a flagpole, hence the term flag hinge. The chief reward of using flag hinges is its piece of cake dismantling. The male person stop is secured to the other but by gravity. Flag hinges are also classified as lift-off hinges.

-

Floating Hinges:

This is a type of swivel that allows some translation of 1 part relative to the other bated from rotating. While behaving like a butt swivel, the door or cover can move away from the fixed role.

-

Flush Hinges:

Flush hinges are designed in such a way that the leaves sit flush against each other. This is achieved past fitting i foliage within the other. This is an reward against butt hinges since flush hinges do non need a mortise or a recess on the surface of the body they are attached to. These types of hinges are used in light load applications.

-

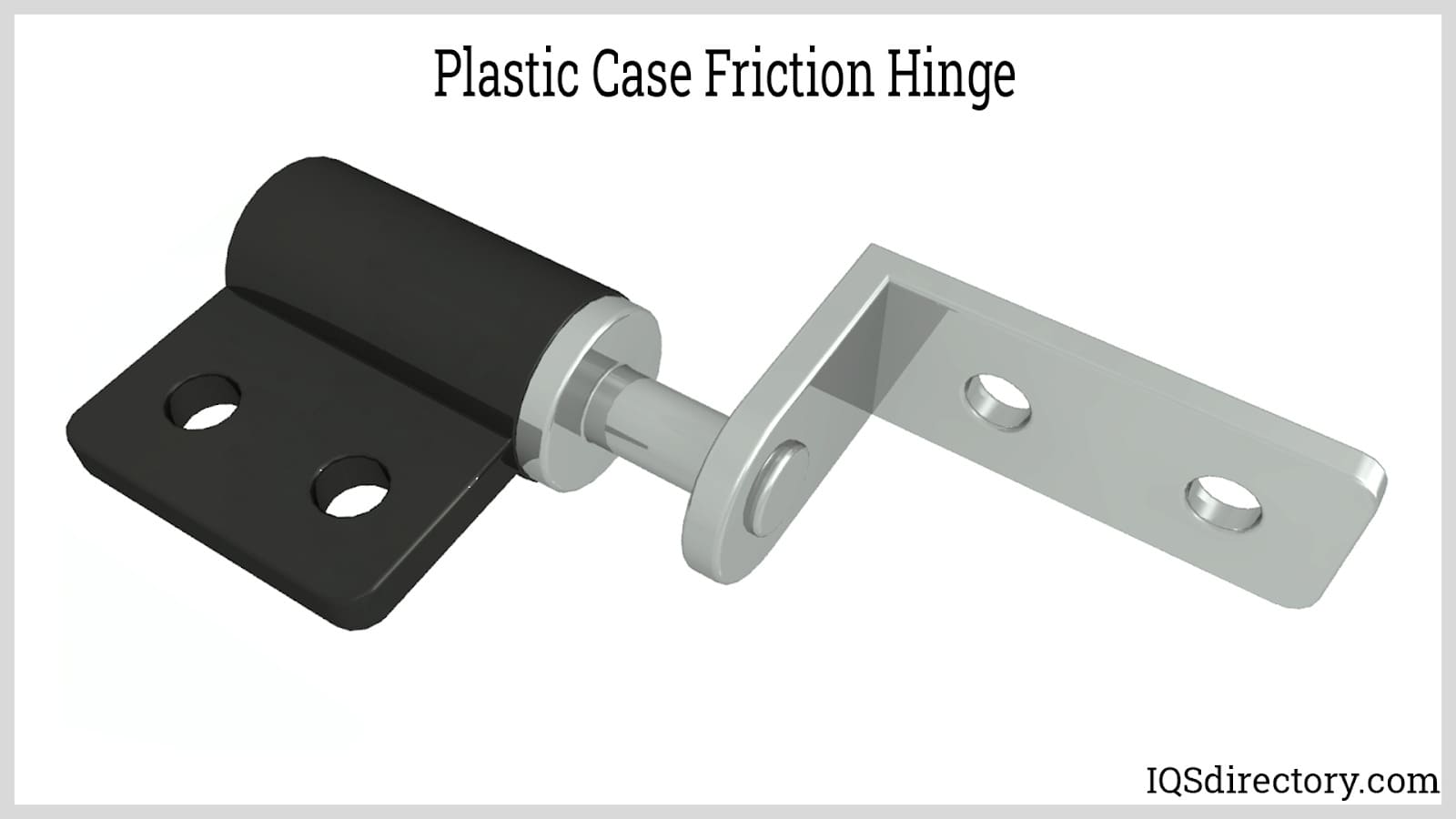

Friction Hinges:

Friction or torque hinges are designed to function like a butt hinge but hold its position over extended periods of time. Friction is adult into the butt which resists motility acquired past gravity or other external force. These hinges are particularly useful in display devices and other electronics.

-

Geared Continuous Hinges:

A geared continuous hinge differs from a butt hinge by using gears and a vertical cap instead of knuckles and a pin for movement. This is useful in joining two heavy objects while assuasive one or both to partially rotate. Despite its strength, a major downside of this type is its express range of movement.

-

H-Hinges:

H-hinges are also mortise hinges with an "H" shape. This shape is due to the smaller length of the duke and pivot every bit compared to the length of the leaves.

-

HL-Hinges:

HL-hinges are the aforementioned every bit H-hinges but with i foliage shaped similar an "L". This is used when the door or the moving part is heavier.

-

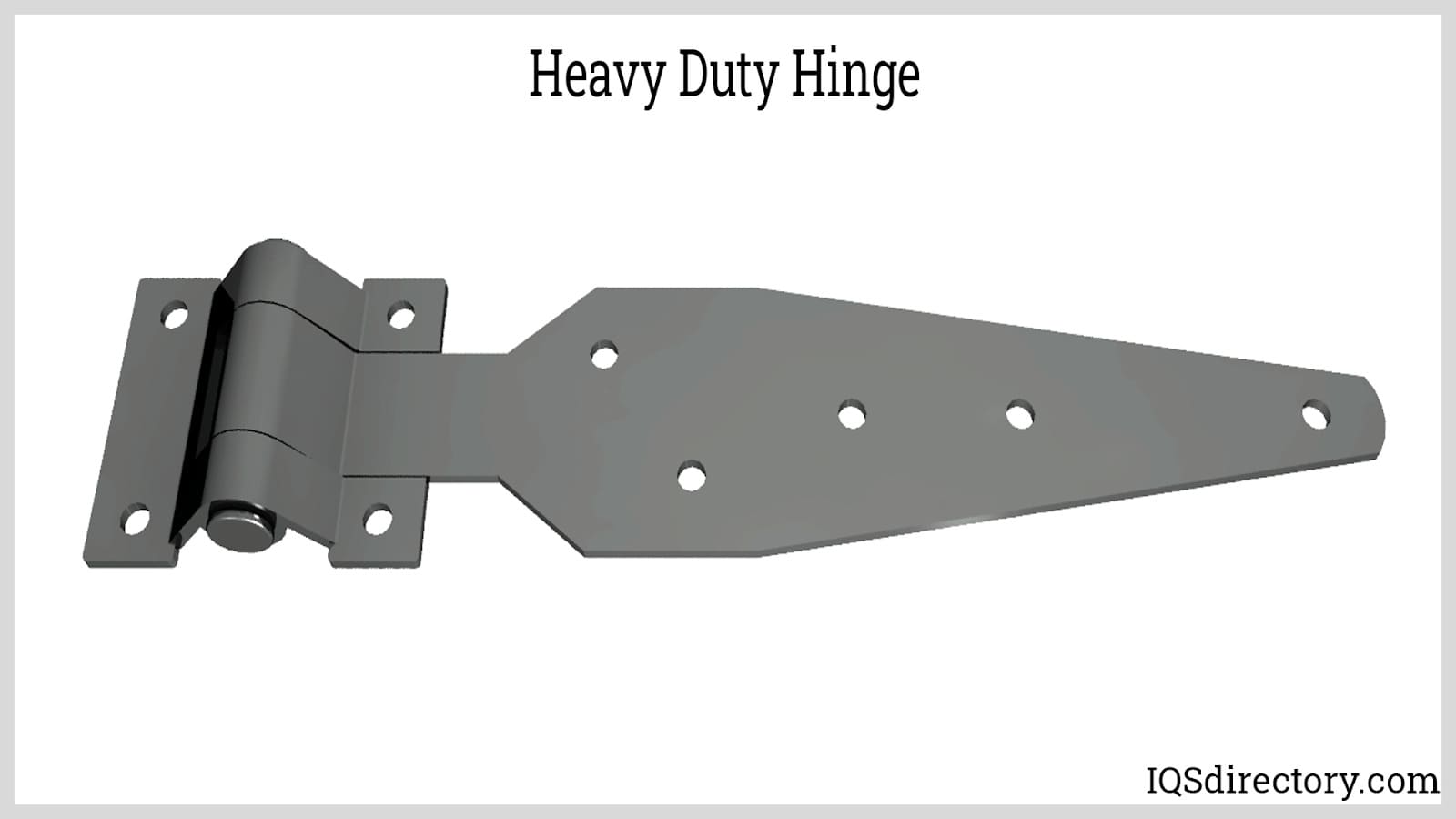

Heavy Duty Hinges:

Heavy duty hinges can be of any swivel design but with an added thickness to the material making information technology stronger. These hinges tin be mortised, surface mounted, or welded depending on the application.

-

Institutional Hinges:

This blazon of hinge features an offset from the pin. The leaf is formed in a mode to create the offset and allow overlaying making it suitable for narrow frames and small clearances. Institutional hinges can be designed to allow an end play of 270°.

-

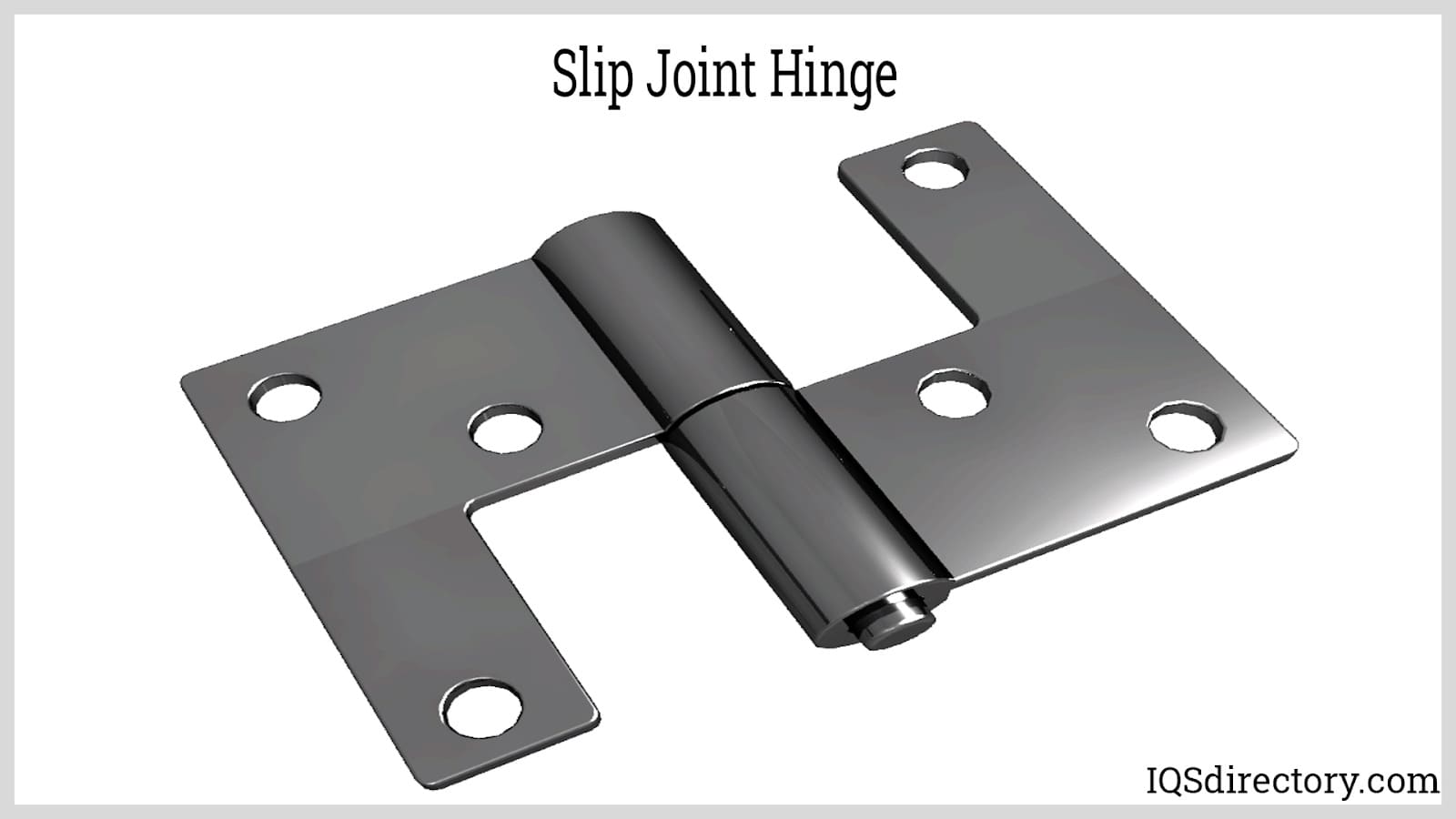

Lift-off, Loose Articulation, or Sideslip Joint Hinges:

Elevator-off hinges, like flag hinges, have male and female leaves in which the male leaf has a permanent pin attached. The leaf length of lift-off hinges can be the same as the length of the pin, unlike the flag hinge.

-

Living Hinges:

Living hinges are different from the other types since it does not rely on knuckles and pins for attachment. It is made from the rigid torso itself where a portion is cut or thinned to permit bending. This type of swivel is commonly seen in plastic containers and packaging materials. Since these hinges are made of plastic, they are inherently protected from corrosion. Polyethylene and polypropylene are the best materials for containers with living hinges because of their excellent fatigue resistance.

-

Offset Hinges:

An first hinge is a modified butt hinge primarily used to increase the width of doorways. The design is similar to an institutional hinge. Opening the door at a 90° angle sets the door about two inches from the doorway, leaving more space for passage. This elementary modification of a butt hinge is a toll-effective way for increasing access space every bit compared to dismantling and constructing a wider doorway.

-

Overlay Hinges:

This blazon of hinge has its leaves folding into each other, like a affluent hinge. These hinges are commonly used in cabinets where insert, full overlay, or fractional overlay is required.

-

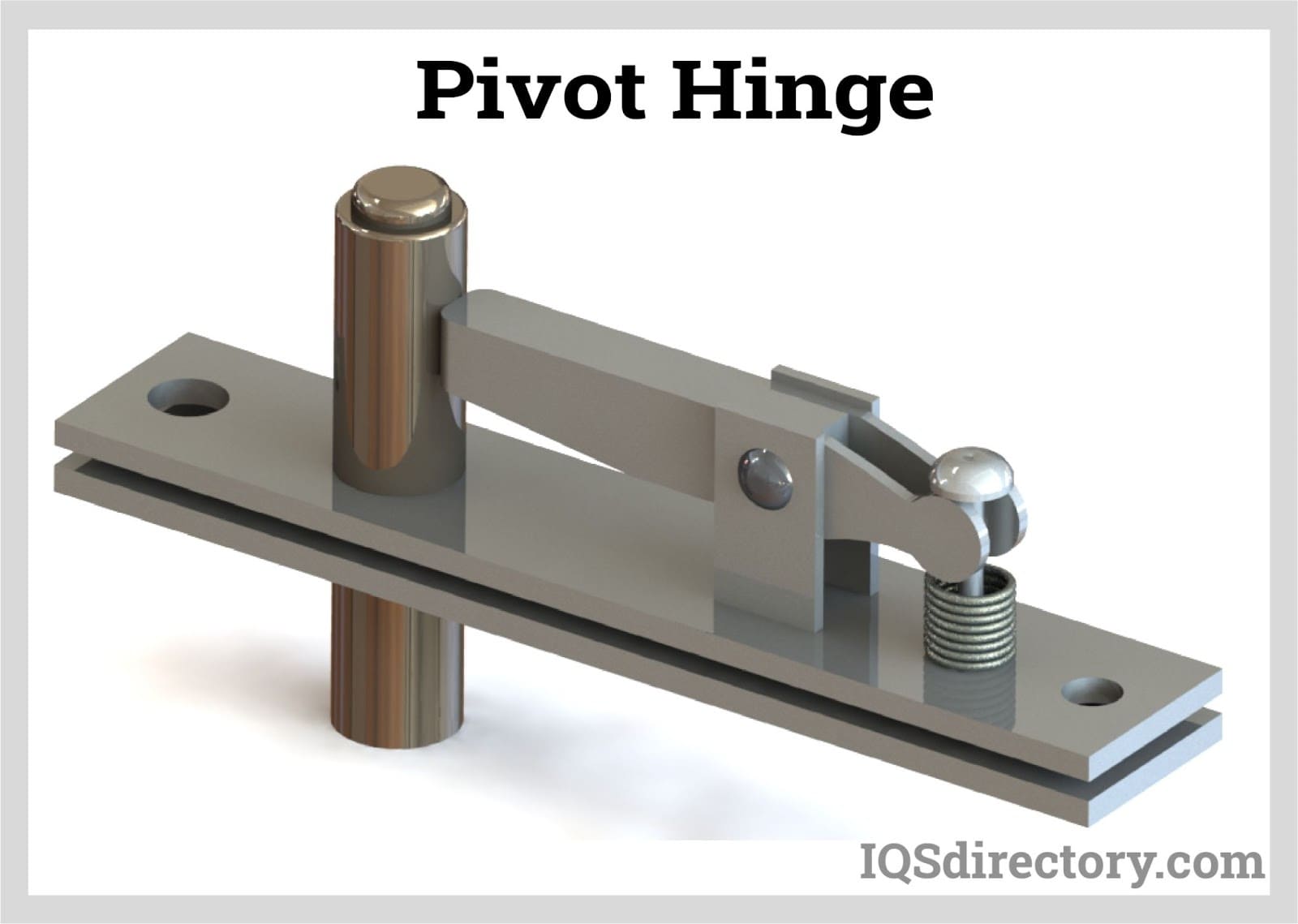

Pivot Hinges:

A pivot hinge has its pins (the pivot) fastened to the peak and bottom side of the door against the door frame. This hinge is dissimilar from the butt hinge where the pins are located at the sides. Pivot hinges allow a wider range of rotation which makes it suitable on doorways with loftier traffic on both directions.

-

Quick Release Hinges:

This type of hinge features a pin release mechanism platonic for NEMA and JIC enclosures. The pivot is turned or pulled to release the hinge.

-

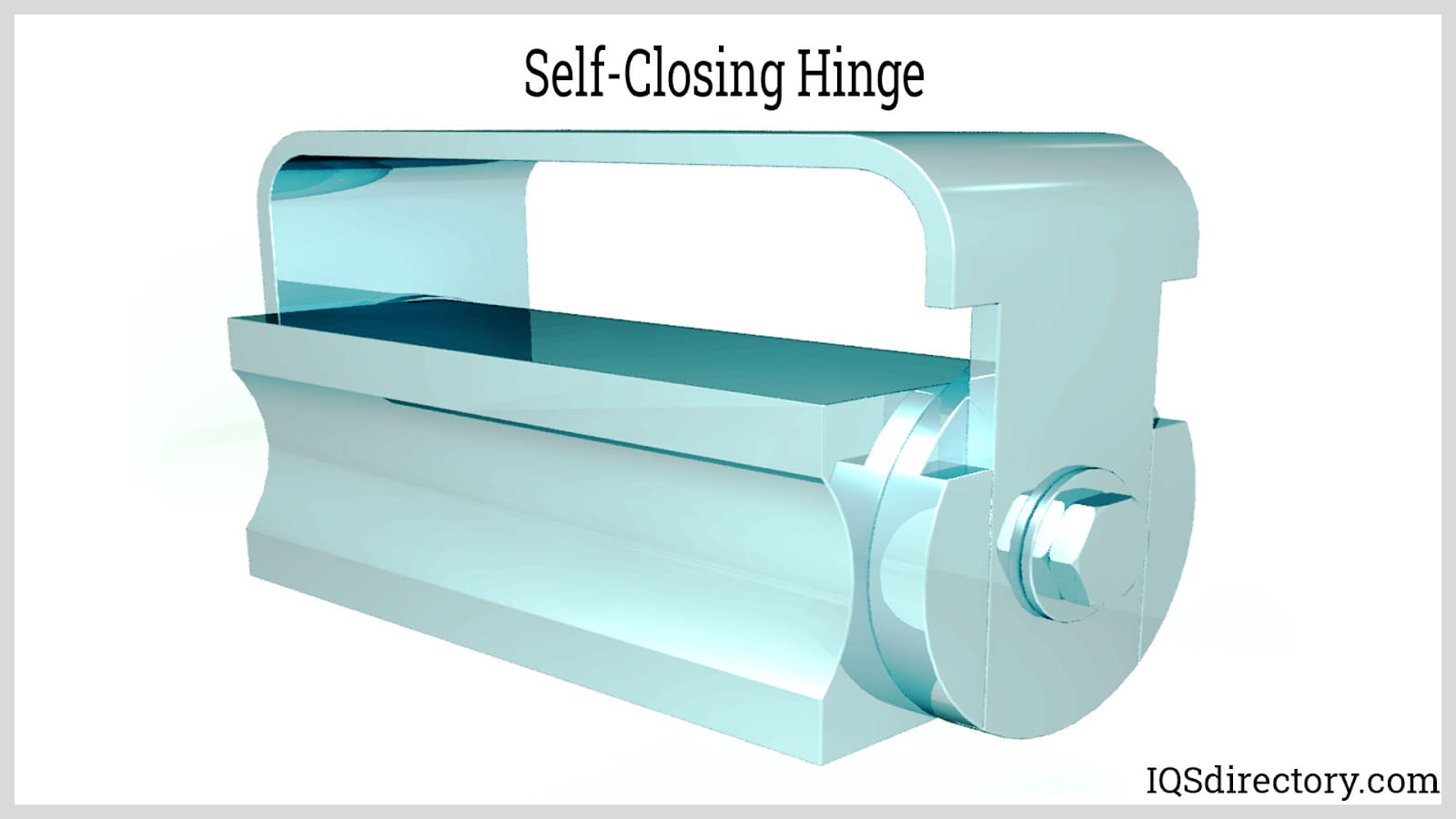

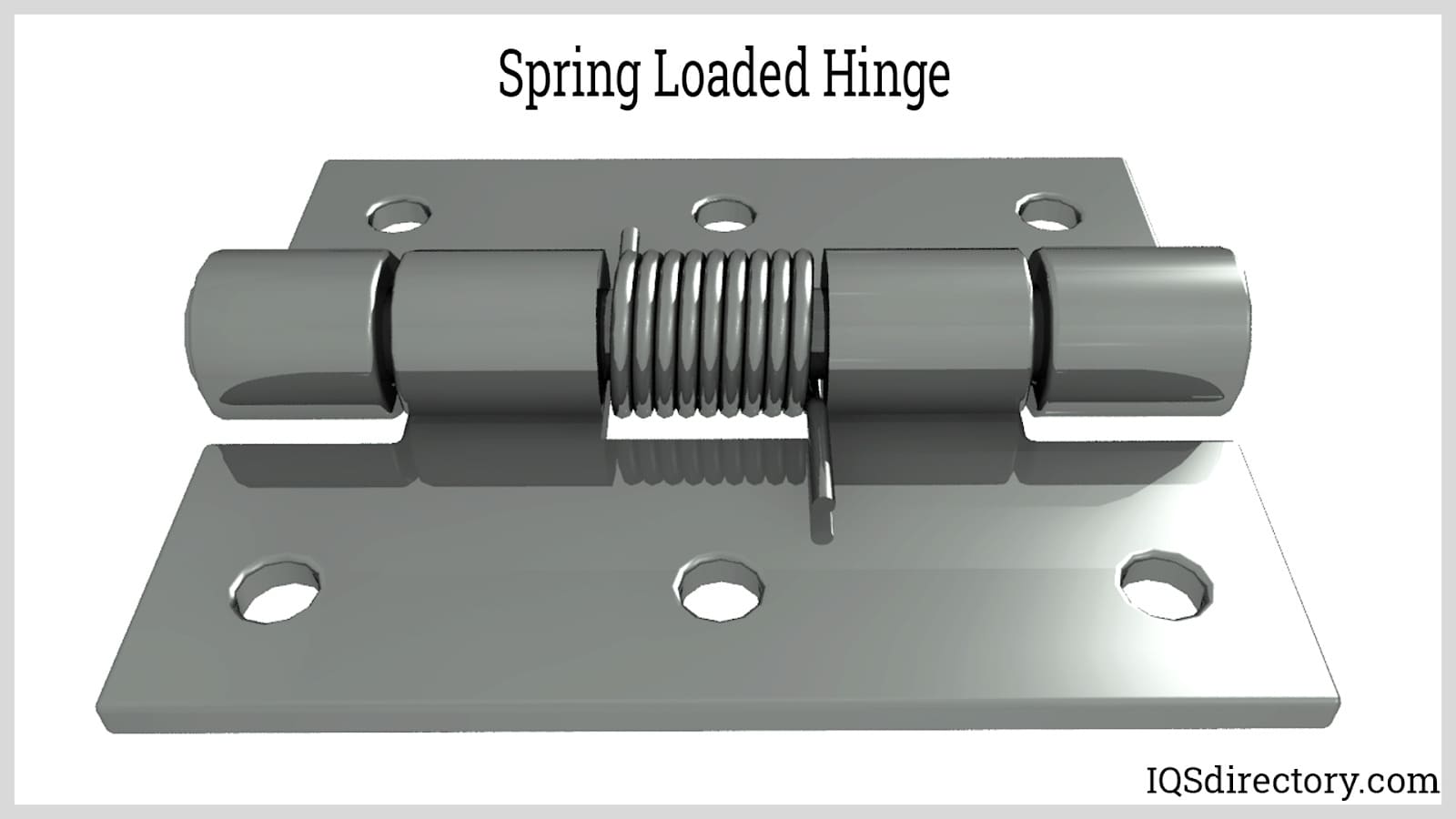

Cocky-closing Hinges:

A self-endmost hinge is a blazon of jump-loaded hinge designed to automatically close doors by means of a jump. The bound exerts a force to shut the door while a damper, either mechanical or hydraulic, causes the rotation of the door to boring down as it closes.

-

Jump-loaded Hinges:

Jump-loaded hinges are hinges fitted with a jump to help opening and closing of the door. One type of this hinge is the self-closing hinge which was mentioned earlier. Some other is the double action leap hinge. Its move is similar to the pin swivel, only with springs attached. The door tin can swing in both directions while the springs automatically close the door in its center position. Depending on the installation it is important to determine if indoor spring hinges or outdoor jump hinges are needed, as weatherproof or waterproof hinges accept important and necessary material differences.

-

Spring Release Hinges:

A leap release hinge, similar the quick release hinge, has a pin release mechanism that allows for dismantling doors without the need for additional tools. This hinge features a pivot release mechanism held into position by a spring. A knurled knob is pushed and turned to release the hinge.

-

Stop Hinges:

This type of hinge is constructed to have a limited cease play. The typical end play of cease hinges is 90°. They can be formed equally a barrel, continuous, strap, and weld-on hinges.

-

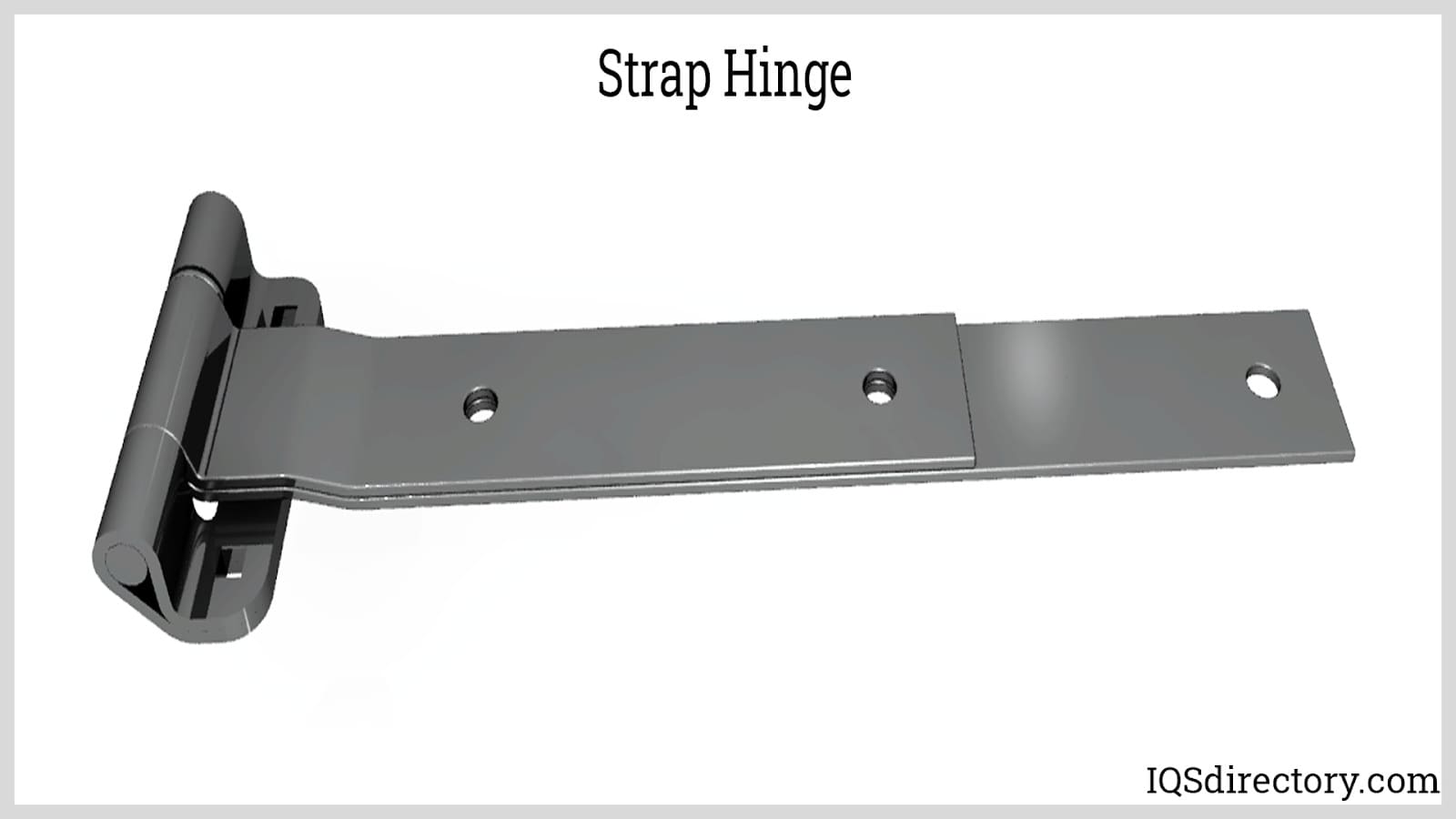

Strap Hinges or Tee Hinges:

Strap hinges are like butt hinges but with a shorter pivot and wider leaves (straps). This type of swivel is non intended to be curtained, just for aesthetics and decoration. These are usually used on garage and shed doors.

-

Weld-on Hinges:

Weld-on hinges are used in metal enclosures or gates where the swivel is needed to be fixed permanently through welding. Their construction is similar to a butt hinge.

-

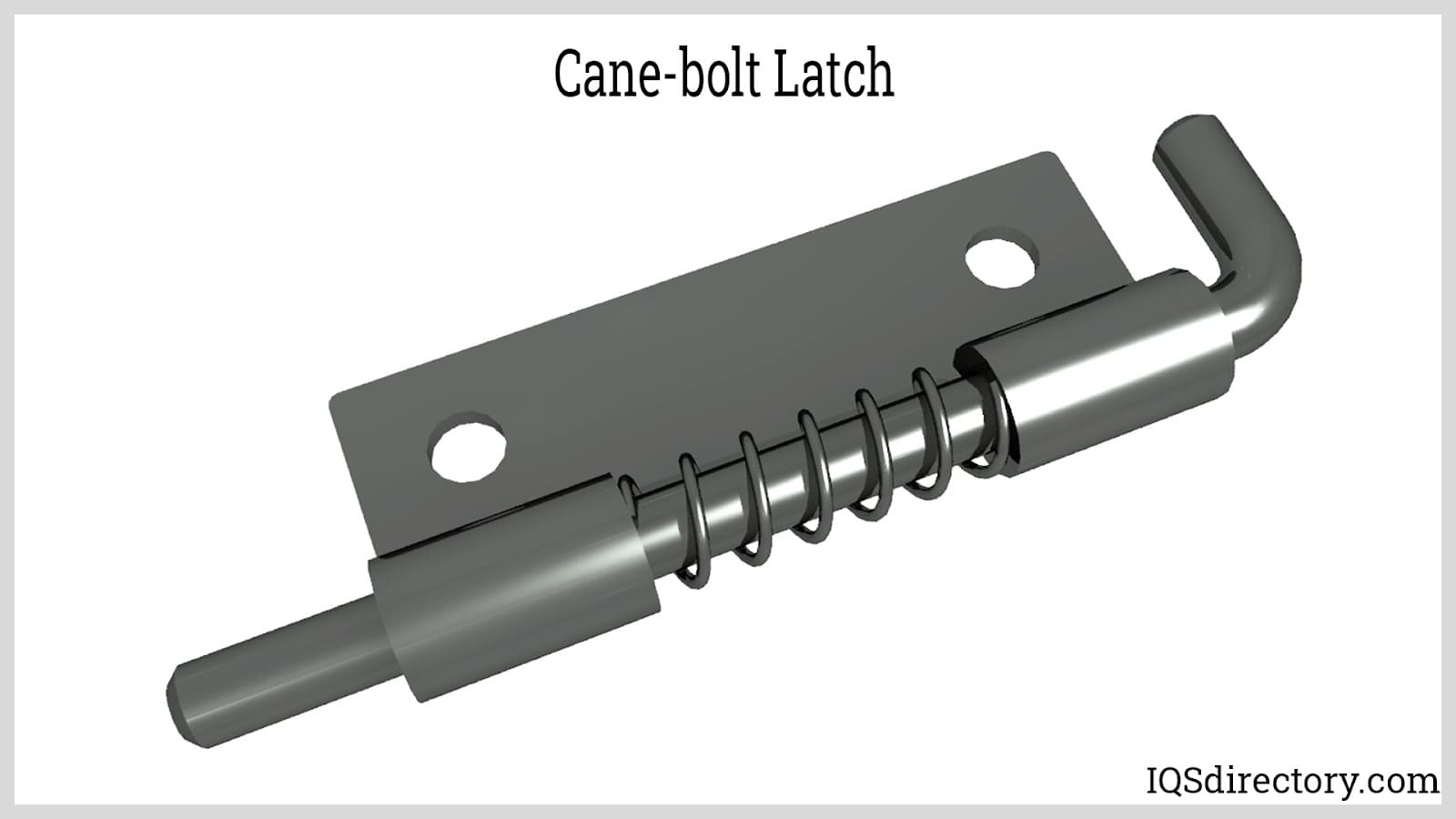

Cane-bolt Latches:

This is a type of bolt anchor used to hold doors in a fixed position, though in some cases, it can also be used equally a hinge. A cane-bolt latch consists of several barrels attached to a moving part, a drop bolt or rod, and a hole stock-still on the mating role.

Damper Hinges

Damper hinges help the slow endmost of doors or lids. It controls the speed of movement. These are also used in toilet lids.

Lift Assist Hinges

These hinges help in light opening of doors or flaps with the assist of built in springs in it.

Detent Hinges

These hinges are used to hold the object in a certain position without whatsoever secondary support. These hinges are used in flip mobile phones as well.

Gravity Hinges

Gravity hinges are used in bathroom doors and they work by using the weight of the door as a constant force for its endmost and opening on its own

Pivot Hinges

The doors where pin hinges are attached open and shut in an unconventional way. These hinges are placed at the bottom and the top of the door and facing information technology in an outward direction making its axis of rotation on the outside.

Drop Hinges

Drop hinges are used in downward openings similar flaps of the Idiot box racks or drawers. These hinges get fully flush when the drawers are opened.

Clean Room Hinges

Clean room hinges are peculiarly designed for laboratories and make clean areas, these hinges take brushes in between the knuckles. This plastic bushing helps remove any dust particles from entering in.

GET YOUR Company LISTED BELOW

Leading Manufacturers and Suppliers

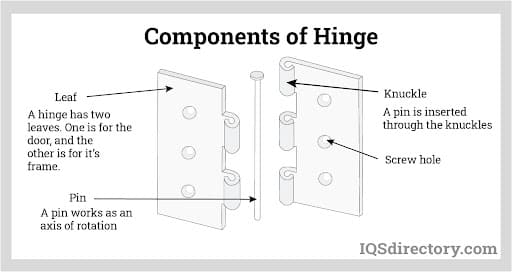

Chapter 3: Components of a Hinge

This section defines the terms mentioned such as leaves, barrels, and pins. Aside from the component terminologies, swivel characteristics are also discussed. These characteristics define the specifications for manufacturing or purchasing a hinge.

Swivel Components:

-

Leafage

This is the plate that extends laterally from the knuckle or barrel. This is the part that is being fastened to the fixed or moving body either by screwing, welding, or gluing. The leaf attached to the moving part revolves around the pin.

-

Knuckle or Barrel

This is the hollow cylinder fastened to the leaf where the pin is slid through. Considering the hinge equally a machine chemical element, the knuckle can too be referred to as a begetting.

-

Pin

The pivot is the rod or shaft that runs through the knuckles which holds the leaves together.

As shown in the figure, the flat surfaces are the leaves of a hinge. Each leaf is fastened to the parts that are being joined. The duke, or holes that can be seen in the leaves, are used for screws and bolts to attach to the hinge. The pivot is so placed between these two leaves to join them to each other and help the rotation. Usually, the hinges requite a revolute joint meaning that the rotation is only forth the axis in one direction. This limits the all axis rotation of the objects that are joined with the hinge. Every bit a single caste of freedom, a single pin cannot handle this kind of movement. Some other hinges requite a complex motion such as in doors and windows. Four pins are used in these circuitous motion hinges.

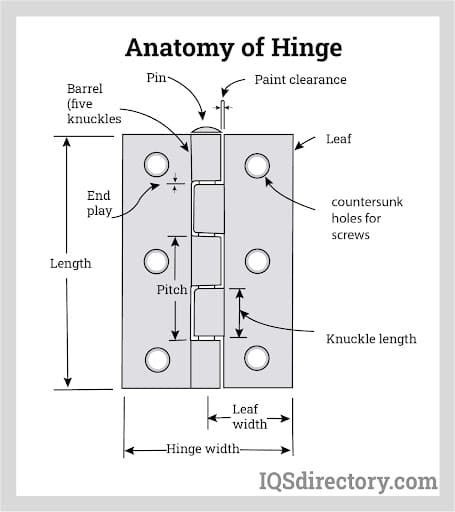

Hinge Terms:

-

Leaf Length

This is the dimension of the leaf as measured to the side parallel to the pin's centrality.

-

Joint Length

This is the length of one knuckle or barrel.

-

Barrel Length

This is the overall length of the barrels every bit measured parallel to the pin'due south centrality.

-

Foliage Width

This is the dimension of the leaf as measured to the side perpendicular to the pin'south axis.

-

Open Foliage Width

This is the overall width of the swivel equally measured across the pin.

-

Paint Clearance

The pigment clearance is the dimension of the gap between the outer face of the knuckles and adjacent edge of the leaf.

-

Side Play

Side play is the degree of movement of the leaves perpendicular to the pin.

-

End Play

This is the caste of axial movement between the leaves.

-

Pitch

Pitch is the distance betwixt the end of a knuckle and the cease of the next knuckle on the aforementioned leafage.

-

Leafage Cloth

Mutual leaf materials are steel, stainless steel, aluminum, brass, and bronze.

-

Gauge

This is defined every bit the thickness of the leaves.

-

Slop

Slop is the loose athwart movement of the leaves relative to the pin.

-

Standard Assembled

In this assembly, the leaves lay flat on the same aeroplane when in an open up position.

-

Reverse Assembled

In this assembly, the leaves extend laterally from reverse sides of the pin. Reverse assembled hinges cannot close with its leaves in parallel.

-

End Plate

Cease plate is the axial motion between the leaves forth the pin centrality. This helps in rotation of the leaves without its binding and can exist measured past the distance between the knuckles when both leaves are aligned.

-

Swivel Width

Swivel width is the altitude between the 1 cease of the leafage to its other end and is perpendicular to the pin.

-

Hinge Length

Information technology is the leaf length parallel to the pivot.

-

Knuckle Length

Information technology is the length of the knuckle that is parallel to the pin.

-

Knuckle Pitch

Pitch is the distance of the end of the knuckle to the same edge of the next knuckle on the same foliage side.

-

Door Stop

It is the loose athwart movement of the leaf relative to the pivot.

Affiliate 4: Things to Consider When Purchasing Hinges

There are certain factors to consider when purchasing a hinge. Since the swivel has moving parts and carries loads exerted both past the moving torso and the external loads, the swivel most of the fourth dimension becomes the weakest point. Dynamic loads practical to the hinge volition cause it to fatigue over time causing sagging on the door or gate. Moreover, hinges can but have a maximum thickness because of manufacturing limitations or infinite restriction. Hinges must be specified properly with the right dimensions, cloth, and mechanical properties fit to the application.

-

Load

The load to exist carried is a central factor to consider when specifying a hinge. This will decide the dimensions and the material required for the application. In obtaining the right load specification, it is of import to consider not only the weight of the moving part, which is usually the function being carried, but besides external and dynamic loads. Also, the door's center of gravity will cause a moment or torque onto the hinge. This moment may cause the door to somewhen sag, specially when the door is wide and heavy.

-

Required or Allowable End Play

Some hinges have limited athwart movement such as the geared continuous hinge. The part or may need to revolve a full 180° or just 90° depending on the application. Bank check if the space tin can accommodate the door swing and if the swing will bear on access through the door. There are different types of hinges to choose from depending on the application.

The required movement may also demand friction or spring-loaded hinges for fixing the position of the moving role. The laptop covers, camera tripods, and ventilation screens are popular examples of devices that use friction hinges.

-

Swivel Orientation

Hinge orientation is the management of end play or how the swivel rotates or moves relative to the door. Hinges can be right-handed or left-handed. Choosing between correct or left-handed hinges depends on the swing and type of the door.

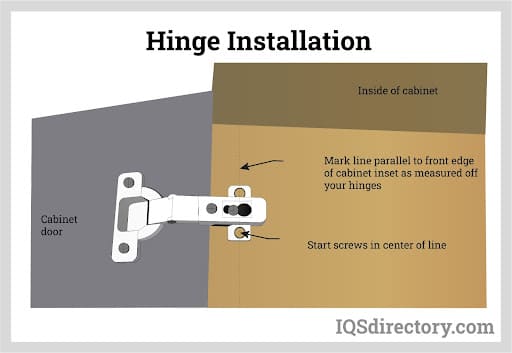

-

Installation

Some other factor to consider is the method of fastening the hinge to the moving and fixed parts. Hinges can be welded, bolted, or screwed on the frame which typically depend on the type of service or amount of load to be carried. Moreover, hinges tin can be installed with different mountings such every bit surface, curtained, flushed, overlayed, and then on.

-

Aesthetics

Hinges used for article of furniture and doors usually have good aesthetics imparted on them. This may mean decorative designs of hinges as what tin can exist seen on butterfly and strap hinges. Besides, aesthetics may also require hinges to be curtained so that the article of furniture will have a continuous, uninterrupted wait.

-

Hinge Corrosion Resistance

The type of surroundings, whether outdoor or indoor, volition affect the fabric specification of the hinge. For applications requiring corrosion resistance and high strength, stainless steel is the cloth of choice peculiarly in salt environments. Plastic hinges are corrosion resistant besides, but without the high strength. If stainless steel is too expensive, galvanized steel works equally well. Contumely and bronze offer good resistance against outdoor weather and are suitable for decorative purposes because of their natural patinas.

-

Boosted Features

Additional features are special characteristics of a hinge to allow or perform a specific function; for example, springs and pneumatic dampers for spring-loaded hinges. Multiple features can be designed to a hinge which can include pins, grease fittings, bearings, bushings, screw covers, etc.

Chapter 5: Common Hinge Manufacturing Processes

Hinges tin be manufactured either by casting, extruding, forming, or milling. Each process has its own advantage and is chosen based on the hinge profile, material, cost, and available technology. Have forming for instance, which is a cheap and straightforward way to mass produce hinges with acceptable tolerance. However, since its products accept low strength. i may opt to use milling or casting as a process instead if heavy duty hinges are required.

-

Casting

Casting is a process where liquid metal is poured into a mold cavity that contains the shape of the product. Casting is 1 of the earliest metalworking processes used to industry hinges. To create a cast hinge, a replica of the desired shape is fabricated onto a piece of wood, metallic, plastic, or plaster. For the barrel, an additional figure made of sand or metallic shapes the internal to make it hollow. Next will be the grooming of the mold where a special type of sand is packed effectually the design contained in a frame called flask. One time the sand is packed, the swivel pattern tin can so be removed. Afterwards the mold is prepared, the molten metallic is poured into the cavity and left to solidify. In one case solidified, the mold is and so broken, and the sand is removed from the casting. The cast is then cleaned, smoothened and heat treated to enhance its characteristics.

-

Extrusion

Extrusion is a metalworking process (although applied on plastics besides) where the metal is forced through a die with a desired cross-section. The resulting shape volition accept a fixed cross-sectional profile. To create a butt hinge, this extruded metal is then milled and cutting according to the required foliage length and pitch. Geared continuous hinges, on the other hand, does not demand farther milling since its cross-section is fixed throughout its length. Aluminum is the textile commonly used for extruded hinges. The gauge of the swivel can hands be made thicker by using a die with thicker hollow sections, thus making the hinge stronger.

-

Forming (Stamping)

Metal forming a swivel involves a thin blank sheet which is cut and subjected to plastic deformation using forming tools such as rollers and dies. Like casting, metal forming through hot forging is i of the earliest methods for producing metalworks. A common forming process is stamping where blanks are pressed onto a die. The dies are designed so that the required pressure level exerted volition accurately produce the required shape of the hinge. Stamped hinges have college dimensional precision that can be produced at a lower cost than casted and extruded hinges. Furthermore, the hinges are common cold worked (for cold forming processes) significant the resulting material is made stronger and harder for its gauge. One downside of forming hinges is that the estimate of the hinge is express. The thicker the plate, the more difficult it is to form.

-

Cut or Milling

This procedure involves removing backlog material from a metal workpiece using lathes, shapers, drills, or milling machines. Milling is unremarkably used for producing hinges with precise dimensions. Milled hinges tin can be made thicker, similar to the casting and extruding process.

Afterwards the process of shaping the swivel, secondary processes have place. These secondary processes are a combination of estrus treatment, galvanizing, coating, painting, polishing, and so forth. Rut treatment gives the hinge the desired mechanical properties like toughness, strength, and hardness. Galvanizing, coating, and painting provides corrosion resistance for outdoor environments. Polishing, burnishing, and buffing is done for decorative hinges.

Installation of Hinges

One thing must be considered earlier installing hinges. It is important to maximize the altitude between two hinges, as it helps to minimize the load capacities and prevent door sagging.

Chapter 6: Swivel Applications

Hinges are used widely in all areas of life from medical, industries, military to agriculture.

- Hinges are used in medical fields in heavy lead lined doors that are mainly radiation and neutron shielding, vault doors and medical equipment.

- Research and evolution field uses hinges for heavy doors to protect the laboratories from radiations contamination.

- Military and defence force areas use hinges for armored vehicles, carriers, and heavy doors of secured areas.

- Hinges are widely used in households and buildings for doors, windows, cabinets, Tv set racks, and in many other household items.

- Heavy duty hinges are used in chemic processing plants for behemothic processing containers to protect the environs.

- Hinges are too used in shipping containers to keep them well locked.

- Industries such as petroleum or gas facilities use hinges in their gates to facilitate its movement.

- Hinges are also widely used in illuminating panels such every bit LCD screens, laptop screens and illuminating wall cladding.

- Many marine devices and ships use hinges in their doors as well for loading and unloading of heavy doors with ease.

- Agricultural machinery and construction sites likewise used hinges of different types in their gates and machines.

Conclusion:

- A swivel connects two bodies, usually one stock-still and one moving, which allows angular movement along i axis while preventing whatsoever translation and rotation on the other two axes.

- There are several types of hinges available each with intended awarding. Most hinges are derived from the butt hinge type. Hinges with an entirely different structure are geared continuous and living hinges.

- The main components of hinges are leaves, duke (or barrels) and pin. From these components, characteristics can be defined such as foliage length, stop play, pitch, and then forth.

- Hinges are the usual weak points in structures. Design of hinges are determined past the load, terminate play, aesthetics, and environment. These factors must be balanced to produce the most suitable hinge.

- Hinges are manufactured based on the hinge contour, textile, cost, and bachelor technology. The primeval metalworking processes to develop hinges is by forging and casting. As technology develops, mass production through extrusion, forming and milling are then used.

Get YOUR Visitor LISTED BELOW

Leading Manufacturers and Suppliers

How To Remove Spring Hinges,

Source: https://www.iqsdirectory.com/articles/hinge.html

Posted by: crawfordthly1953.blogspot.com

0 Response to "How To Remove Spring Hinges"

Post a Comment