How To Repair Split Wood Beam

Repairing Structural Timbers – How to Repair Structural Timbers in Situ Using a Timber Resin Splice Kit

Repairing structural timbers, how to repair timber lintels, beams, joists, wall plates and rafters including repairing shakes and splits in timber. Learn how to repair structural timbers while they remain in situ using a timber resin splice kit. This allows you to salvage on costs and hassle as it avoids the need to remove and supersede structural timbers. Too discover out about repairing shakes, splits and cracks in timber.

Repairing Structural Timbers

Repairing structural timber has always been an expensive and fourth dimension consuming performance. From a timber lintel in a Georgian terrace, to a huge necktie axle in a barn conversion, if a new slice could not be spliced, or bolted on, the lot had to come out. Very often, even if it were possible to bolt a new department of timber on, the overlap for the bolts in near cases were so long it was well-nigh similar replacing the entire timber anyway.

To these ends and in this project we volition deal with how to repair structural timbers and we are very pleased to innovate a wonderful new engineering known equally the Timber Resin Splice Organisation.

Removing complete timbers or carrying out traditional splices in joists, rafters and other structural timbers requires considerable opening up of ceilings, floors and roofs, and most people would rather not take their houses apart. In well-nigh cases consummate replacement of a timber will be impossible by traditional means without scaffolding or roof removal, but a TRS will allow the depression disturbance (and therefore cheaper) repair of beams, roof purlins, necktie beams, lintels, joists and rafters. This method tin even be used for repairing flag poles!

If you need any assistance with repairing structural timbers of any type of Structural timber repair, timber splits, shakes or cracks Property Repair Systems staff volition be pleased to give you completely free, no obligation advice on 01626 872 650. The information yous need may be in the project beneath. If not, call them for expert, impartial advice.

Using Timber Resin Splice To Repair Structural Timbers

Using the Timber-Resin Splice Organization a section of timber can exist cut out, in situ, and a new section added. The repair will be stronger than the original.

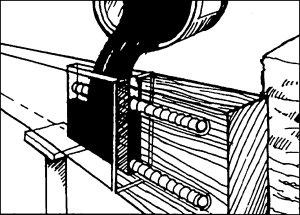

Decayed timber joist replaced with timber resin splice

How is this done? Obviously for the benefit of this project nosotros accept simplified the procedure…But not by much! It really is an unproblematic breakthrough allowing new, treated timbers to exist installed with the minimum of fuss and disturbance.

Timbers are not all accessible from the aforementioned place. While y'all may exist able to get to a flooring joist from the top by lifting a section of the floor, information technology is far easier to access a rafter from underneath. Holding Repair Systems has devised different ways of repairing structural timber, to allow access from all angles.

In the beneath sequence of images nosotros have shown the about basic, repairing a flooring joist that is accessible from first flooring level. We are working in a first floor bedroom with a lathe and plaster ceiling.

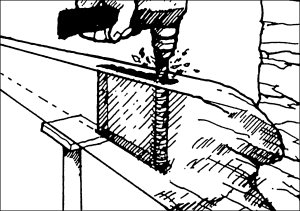

Rotten joist in wall with slots beingness drilled in good role of the timber

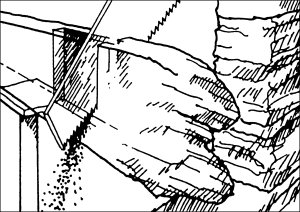

Rotten finish of joist cut off

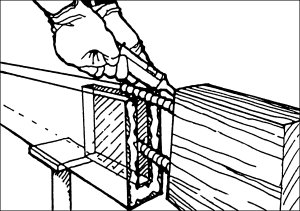

Quick setting paste practical to faces of joist and new stop fixed to existing joist and pushed back into wall. Repair rods nowadays and fixed and set into new joist section

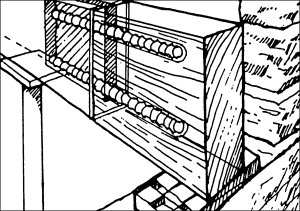

New department of joist stock-still to existing joist showing repair rods set into the new joist section and existing joist section

Resin poured into slots in existing timber that then sets stone hard securing rods in place and securing the two sections joist together

Repairing Cracks, Splits And Shakes In Timber

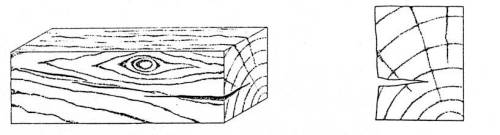

Cracks in timber beams need not impact the overall integrity of the structure. Indeed, cracks in timber beams tin be taken as a positive visual characteristic of the timber, which, in conjunction with the timber grain, distinguish timber from the more than uniform human being-made materials such as steel and concrete.

The integrity of the timber can be called into question when information technology is dumb past cracks, splits and shakes and often in this instance will required the replacement of a axle or rafter which has formed office of the original structure. This can now exist overcome in a bang-up many cases with the use of an injected epoxy resin. We recommend seeking the advice of a structural engineer when information technology comes to these types of structural repairs.

Cracks, shakes, warps and fissures are formed every bit a consequence of the timber giving up moisture and shrinking. This may occur as office of initial drying or subsequent changes, during service, in the Equilibrium Moisture Content. The EMC of timbers within buildings can range from nine% to 14%. Fibre saturation is reached in constructional softwoods at most 28%.

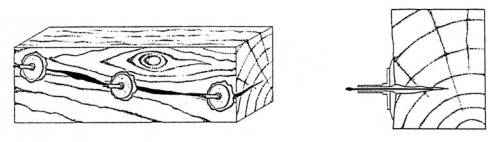

For cracks and splits that are greater than 5mm wide the void tin be filled with an Mouldable Epoxy Mortar, simply if the crack penetrates more than 30% through the timber information technology will be necessary to provide dowels or Epoxy-Glass Bars across the filled section in society to 'stitch' the two halves together.

The advice of a Structural Engineer should be taken with regards to the number, diameter, length and spacing of the dowels. The dowels tin can exist made of glass fibre, carbon fibre, steel or stainless steel. Nosotros recommend the use of epoxy/glass or epoxy coated steel that is then set in a Thixotropic Epoxy Injection Resin.

Splits in timber department

Clean out cracks or splits with a saw blade and vacuum out all sawdust. Fill the cracks with Mouldable Epoxy Mortar.

When the mortar has set drill pocket-size holes, most 6mm in bore through the epoxy into the dorsum of the crack. Blow, or vacuum out the dust. Directly inject Thixotropic Epoxy Injection resin into the pigsty, until the resin flows from the adjacent hole. Go on until all the holes have been injected and cap off each with Mouldable Epoxy Mortar.

Timber splits repaired using Thixotropic Epoxy Injection and Mouldable Epoxy Mortar

Sand off whatsoever excess Mortar and colour finish to accommodate the timber. If stitching is then required the cracked areas tin at present exist cross drilled and epoxy-glass or steel rods fitted in Thixotropic Epoxy Injection resin.

If yous require whatsoever further help and advice on repairing any defects or damage in timber Property Repair Systems proficient staff can assist you and provide further information and advice. Call 01626 872 650 or

Due east Mail: help@propertyrepairsystems.co.united kingdom.

Source: https://www.diydoctor.org.uk/projects/repairingtimber.htm

Posted by: crawfordthly1953.blogspot.com

0 Response to "How To Repair Split Wood Beam"

Post a Comment